Introduction

In Singapore, low tension voltages supplied by the utility has to meet the voltage regulation limits of +/-6% of 230V (single phase) / 400V (three phase). While this is usually the case, there will be times when voltages can be excessively high during low loading periods primarily in areas whereby there are a large proportion of commercial or industrial blocks.

While equipment’s ability to handle steady state voltage variation varies from one equipment to another, in general any equipment which is constantly ‘exposed’ to long periods of overvoltages will suffer from a reduced lifespan. IEC TR 61000-2-14 showed a reduced lifespan of almost 50% when a filament lamp was operated at 5% higher than its rated voltage. Though it will not be as severe for other types of lightings, one should still expect shorter lamp/ballast life.

And with ‘energy savings’ being the buzz words these days, one may consider to reduce the voltages as ‘seen’ by the equipment even further. This is where voltage optimisation comes in. The interest on how reducing voltages can be used to save electric energy has been around for many years now. The results however have been mixed as its effectiveness is very much dependent on the type of loads and its applications.

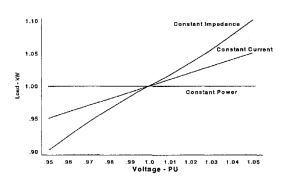

In general, loads can be categorized into 3 Types;

i) Constant impedance:

Power is proportional to (Voltage)2 .

ii) Constant power:

Demand is constant regardless of Voltage.

iii) Constant current:

Demand is proportional to Voltage.

Its relationship to voltage & loading is shown in Figure 1.

Trial Setup

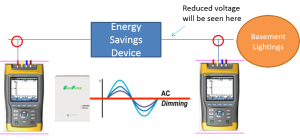

An area in our office was recently equipped with such energy savings device, for the lightings. In our trial, it basically functioned like a “step-down” transformer, reducing the voltage to the lighting circuits. The device has 3 voltage reduction levels; each is a ~13V step down from the incoming voltage.

- Figure 2: Energy Savings Device

Two sets of Fluke 435 Power Quality Analyzers were also installed, monitoring the input and output of the energy savings device; when it was operating at 3 different voltage step levels. Its aggregation interval was set at 1 second and measurement was recorded for 1 hour for each voltage step level.

Lux readings were also taken at various spots in the area, for comparisons against the following guidelines to ensure resultant lux values did not go lower than the recommended levels.

Table 1: Selected Lux Levels Guidelines

| Guidelines | Recommended Lux Levels |

| AS/NZS 1680.2.2 – Recommended Lux level for general office tasks |

320 lux |

| HK Occupational Safety & Health – A guide to work with computers – Recommended illumination for computer desk work |

300-500 lux |

| SS CP87 2001: Industrial Illumination – Recommended Lux level for routine office work |

320 lux |

Results

Table 2: Measurement Results (selected)

| Parameters * measured at input |

Without energy savings device | Step 3 (reduction of approx 39V) |

| Voltage | 238.94V – 242.02V | 238.49V – 240.44V |

| Current | 8.778A – 9.03A | 5.197A – 5.272A |

| Power | 1207.437W – 1249.052W | 811.404W – 825.791W |

| Power Factor | 0.57 – 0.58 | 0.65 |

| Energy Consumed | 1.239 kWh | 0.818 kWh |

Interestingly, most occupants (with the exception of one person) working in this affected area did not notice the dimming of the lights.

In this short trial, the reduction of the voltage to ‘Step 3’ (which resulted in the dimming of the lightings – lux value reduced by 53 lux on average) achieved a 34% of savings in kWh consumption.

Conclusion

Voltage reduction does bring savings in energy, if applied on the right load and application.

Before one decides to use such devices, it is important to check what type of loads will be connected. As seen in Figure 1 earlier, not all loads will benefit in terms of energy savings when voltage is reduced. Even in cases of lightings, not all types will be suitable.

Its application matters as well. There is little benefit if resultant lux level becomes too low and the employee has to use a desk lamp to complement the office lightings. Or that an equipment has to operate longer to achieve the same objective (eg. A kettle to run longer to boil the same amount of water, under a reduced voltage state).