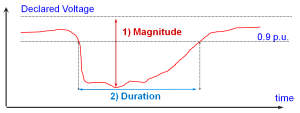

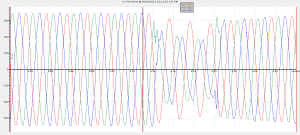

In Singapore, a voltage dip is defined as per EN50160; “a sudden reduction of the supply voltage to a value between 90% and 1% of the declared voltage, followed by a voltage recovery after a short period of time; between 10ms and up to a minute”. Typically it lasts less than 200ms. Two things matter in the definition of a dip. See Figure 1.

1) Magnitude: This typically reflects the fault severity and also the proximity of the monitoring point to the fault location.

2) Duration: The timer starts when the voltage falls below the 90% threshold and ends when all voltages are equal to or above the 90% threshold. This is very much dependent on the time taken to isolate the fault and the nature of loads connected.

The Utility company here has a power quality monitoring system in place; from voltages 22kV and up to 400kV. As these are 3 phase 3 wire systems; line to line voltages are used in the definition of a dip. When there is such a dip, the worst dip by magnitude and its duration will be published by the Utility.

There is a significance of such definition being used in the 66kV and 22kV networks, whereby it is a resistively earthed grounded system (thru the neutral ground resistor). Here, a single phase fault will not be a registered as a voltage dip as the other two non-faulted phases will swell; ‘compensating’ the faulted phase. This will result in a drop of voltage (line to line) of usually less than 10% (hence not a dip). The Utility company here described such events as ‘Voltage variation’.

In recent times, voltage dips seem to be quite frequent in our office at 16 Boon Lay Way, Tradehub21. Tradehub21 is one of the many commercial buildings located in this Jurong East region; near to the International Business Park and also shopping malls like IMM, JCube, JEM and Westgate.

In the last 5 months, our office has recorded a total of 3 voltage dips; two originated from the Utility’s 230kV transmission fault and one which occurred last Friday due to a 22kV Customer’s Installation fault (along Jurong Gateway Road). It is fortunate in a way that this area is not a Semiconductor Hub, as just one dip will have costly implications on a semiconductor plant, let alone three.

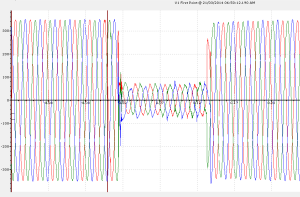

A three-phase 22kV fault; Dip magnitudes at 22kV will be similar.

However, this is not to say that commercial buildings and shopping malls are immune to the effects of voltage dips. Here are the common known effects of voltage dips in a commercial building / shopping mall setting.

1) Chiller System

It is a known fact that chillers plants and its related equipment are sensitive to voltage dips. Relays, control contactors and the electronic/computerized controls may drop off during dips, hence causing the trip. The impact to building occupiers is small; as these effects are likely to be transparent to them; or at most minor discomfort due to a slightly raised ambient temperature.

Possible Mitigation

The sensitivity is sometimes made intentionally (and at times over-conservative) as there is a concern on possibilities of damage to the motor due to the high transient current upon normalization of system voltage (hence it is better to trip). A consultation with the Chillers’ OEM is almost necessary if one decides to protect its control circuits. This is to ensure that it will not result in damaging the motor.

Chiller controls can be secured with on-line UPS or voltage dip mitigation solutions like MiniDySC from SoftSwitching Technologies. Sensitive relays can be identified and replaced. Another option is to enable the Chiller for ‘Auto-Restart’ function if allowable.

Having an internal thorough proper restarting procedure of chillers in the event of tripping due to voltage dips in the network is also a form of ‘mitigation’ as it reduces the downtime of the Chillers. This usually needs close co-operation with the Utility company or install a permanent power quality monitoring system in the building to determine where the origin of the voltage dip (internal fault or fault from the Grid).

2) Lighting Circuits

During a voltage dip, flickering of the lights can be observed. In general, problems only arise when High Intensity Discharge (HID) lamps are used. These types of lightings are known to be sensitive to voltage dips and temporarily extinguish after a voltage dip. Re-ignition time usually takes up to 10 minutes.

Possible Mitigation

For HID lamps applications, one possible mitigation is to re-fit with “hot re-strike” igniter for instant lighting restoration. In the use of HID lamps in “critical areas”, it is best to deploy them alongside normal type of lightings (for eg. Fluorescent lightings), so as to avoid a ‘total blackout’.

In addition, occurrence of voltage dip across three phases is rare; hence the even distribution of lightings across the 3 phases can avoid a ‘total blackout’ during a voltage dip.

3) Escalators

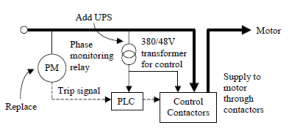

During a voltage dip, the control contactors and PLC of the escalator may drop off. Another cause could be the activation of the phase monitoring relay, which is meant to activate upon loss of mains.

Governed by the Singapore Standard CP15:2004, escalators are designed to be brought to rest in a largely uniform deceleration in the event of loss of mains (thus not a safety concern). However public image may be affected.

Possible Mitigation

The control contactors and PLC can be secured through adding an uninterruptible power supply (UPS) and the phase monitoring relay can be upgraded to a relay equipped with a time delay for up to 0.2 sec. See Figure 6. This is based on CLP Power Hong Kong’s experience in voltage dip mitigation for escalators. It is also documented in Hong Kong’s” Code of Practice on the Design and Construction of Lift & Escalator.”

My personal accounts in conducting voltage dip tests on some of these escalators showed that in general, a voltage dip of more than 40%, regardless of duration that affects the supply to the control circuits will result in the escalator to stop. Mitigation equipment such as the MiniDySC was found to be an effective solution against such events.

A full implementation of such mitigation however will need further tests with the OEM escalator’s specialists to ensure that safety features related to its braking will not be compromised. Additionally, it may also require slight deviations from the existing CP15 as similarly re-defined in Hong Kong’s Code of Practice for Lifts & Escalators.

4) General Circuits

General circuits served by miniature circuit breakers (MCB) have also been reported to have tripped after a voltage dip. Immediately after a voltage dip, some MCBs may tripped due to large in-rush current drawn by motors, switch mode power supply, circuits containing control transformer, etc.

Possible Mitigation

Normally, if the MCBs are properly sized to cater for such ‘inrush’, the circuits should not trip.

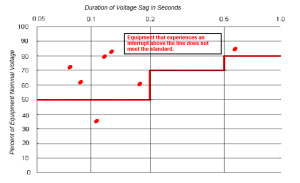

SEMI F47

When it comes to voltage dip mitigation, the word “SEMI F47” will most likely to crop up. Without going into details, it is basically a minimum ride-through specification for semiconductor tools and processes as the semiconductor industry are most prone to voltage dips due to the nature of its operations. See Figure7.

However it must be noted that even such specification does not translate to 100% availability during a voltage dip as dips that are required for compliance with this specification occur between one phase and neutral, or between one pair of phase, at a time only. Hence for these 3 voltage dip incidents mentioned, a SEMI F47-rated equipment will also not guarantee you 100% availability.

To put in simply, in the SEMI F47 specification, an economical balance has been chosen such that semiconductor processing equipment which meets the requirements will be immune to most, but not all, real-world voltage dips at semiconductor plants.

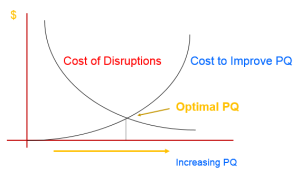

Similarly if one is to consider mitigation equipment, a cost-benefit analysis has to be conducted as such mitigation do not come cheap. A historical dip statistics of the area from the Utility Company should always be among the first things to be obtained.

Faults (and hence voltage dips) are inherent in all power systems in the world. The frequencies of such occurrences can be minimized but not eliminated. Minimization requires the cooperation of all Stakeholders; the Regulator, the Utility company, the Licensed Electrical Engineers and Customers alike through regulations, regular preventive maintenance and condition monitoring.

And if need be, voltage dip mitigation equipment can be employed for those with sensitive operations or processes, albeit it will come at a price. But the price of leaving it to chance may even be greater (see Figure 8). Ultimately the user has to decide.