What is a power quality problem, one may wonder?

There are many definitions to this out there but my personal favourite will be

“Any power problem manifested in voltage, current, or frequency deviations that result in failure or misoperation of customer equipment”.

The keywords here are “Customer Equipment”. If it does not affect the operation of the equipment, it is not a problem (yet).

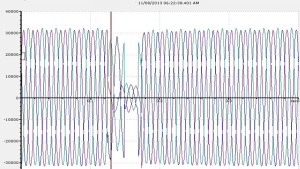

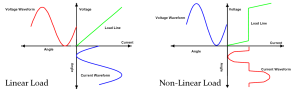

For instance, almost every load that we have today is a non-linear load, contributing harmonic current and hence distorting the supply voltages.

At the beginning, it will probably not be a an issue, but over time if not keep in check and with more non-linear loads added, the supply voltages will be distorted further and eventually equipment may start to fail/misoperate.

The problem is made worse if design considerations were not made to ‘cater’ for this harmonic loads (eg undersized neutral cables) and no control was made to what type of equipment (whether it meets relevant product emission standards or not, etc) can be connected to the network. In this situation, a combination of equipment control and benchmarking of power quality indices is needed (more on this in my future posts).

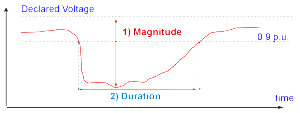

Other than harmonic distortion, other power quality problems include voltage transients, frequency variations, flicker, leakage currents, in-rush currents and voltage dip/swell (just to name a few).

Here in Singapore. the utility company, SP PowerGrid, states in their FAQ that the most important power quality concern in Singapore is voltage dips. This is because a dip will have significant economic impacts on the sizeable semiconductor industries primarily located in Marsiling / Woodlands and Pasir Ris / Tampines area. These semiconductor plants have equipment which are sensitive to these milliseconds variation of the supply voltage. A dip may result in their equipment to trip, halting productions which eventually lead to a host of other costly problems.

My experiences showed that while many of such equipment in the “Facilities” side (Eg variable speed drives to the pumps) are quite well-protected (SEMI F47-rated at least), many equipment in the “Tools” side are not. And one has to take into consideration too that the SEMI F47 has its own limitations as well (more on this in my future posts).

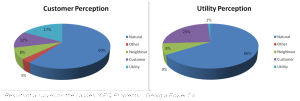

This is not to say that other power quality problems do not exist in Singapore. Things like excessive harmonic distortion for instance are “localized” problems, usually more apparent in the Customer’s end (low voltage side). It is only seen in the Grid’s high voltage side (6.6kV and above) if the problem has escalated considerably.

Having worked for the utility, I do know that there are pockets of the transmission / distribution network that have breached the limits set aside for things like harmonic distortion and flicker. No equipment were known to be affected (yet) and at times, it can also be a complex problem for the utility company to pinpoint the chief cause of the problem, as the grid network is very vast. I believed this is a challenge for many other utility companies worldwide.

Linking back to my favourite definition of a power quality problem, it is a misconception that a PQ problem can only be solved by putting expensive PQ meters / monitoring instrument. A PQ meter is just one of the many tools to aid the PQ investigator. Other tools include earth loop measurement device, earth tester, Infrared Thermal Scan, etc. It is also another misconception that once a PQ monitor is installed, it definitely can pinpoint/solve the problem.

Remember the inputs to the PQ meter is just voltage & current. It is not some “magical” troubleshooting instrumentation. The selection of what PQ meter to use, its settings, the placement of such meters and more importantly the experience of the PQ investigator matters.

p/s: I will share my experiences on the use of various PQ meters in future posts.