The causes of PQ problems can be divided into two main causes

1) Deficiencies and disturbances in the supply

and / or

2) Caused by the nature and behaviour of the consumer’s load and installation

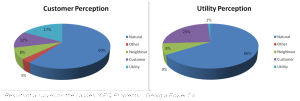

Here it shows the results of a survey done by Georgia Power Co, from the perspectives of the Customer and Utility

However from my experiences, the percentage of blame towards the service provider takes almost 99% of the time here in Singapore.For instance, in a large manufacturing plant setting, the blame on any failure on the “Tools” side will almost exclusively go to the Facilities department (sometimes even without thorough checks on the equipment).

For smaller Customers, tripping issues on their equipment will usually leads to a call / complaint to the Utility almost immediately.

Back in my time working for the utility company, I have experienced countless times whereby my power quality measurements / monitoring showed that the cause of such trips, were actually caused by the Customer themselves (usually a case of high starting in-rush of Customer’s own equipment).

I guess this is the ‘Blame Culture’ here in Singapore. Nothing related to engineering here. Will love to hear experiences from overseas.

As with most things, solving a power quality problem ranges from the very obvious / simple (for instance the above example) to the very complex (especially when it comes to “intermittent” issues).

Personally, I have developed my own checklists (improved over time from own experiences and others) and takes a structured approach at every power quality problem. You should too, if you are new in this area.

Typically, it will begin with a site visit to gather facts/information from relevant parties and conduct baseline site measurements (eg snapshot PQ measurements, IR thermal checks, checking the earthing system etc). It is also important to ask many questions to different people involved. Sometimes you may even get contradicting answers from them! But nevertheless, their answers will give you some clues on what the problem is.

It is from the review of these data (facts and measurement results) that will enable the PQ investigator to form hypothesis what are the likely causes and determine the next course of action necessary to best serve the Customer’s needs.

If the problem happens to be very direct and obvious to identify, the investigation will end here and a report will be formulated on possible ways to solve the problem.

However most PQ investigations will require a further in-depth survey into the electrical system concerned to identify the underlying problem. This will usually require strategic placement of a number of power quality meters simultaneously over a period of time (typically one business cycle) at various levels of the electrical network for data comparison and correlation. Things like sources of harmonics can usually be determined thru the use of power harmonic flow. Sources of flicker on the other hand can be determined thru comparison of its loadings and the flicker trends recorded.

I was a trained combat medic back in National Service, so I will like to use an analogy from the medical field here.

It is akin to seeing a doctor when one is ill. The doctor will firstly ask questions and conduct simple tests on the patient. If the illness is obvious, the patient will be prescribed specific medication and sent home. Otherwise, the patient will be recommended to undergo further tests at the hospital to narrow down / determine the causes of his illness.